- Categories

- Produits électroniques

- Beauty / Personal Care

- Furniture / Building Materials

- Mécanique automobile

- Vêtements pour femmes

- Home Department Store

- International Logistic Service

Produits électroniques

Produits électroniques

Beauté / soins personnels

Beauté / soins personnels  Meubles / matériaux de construction

Meubles / matériaux de construction  Mécanique automobile

Mécanique automobile  Home grands magasins

Home grands magasins  Services logistiques internationaux

Services logistiques internationaux

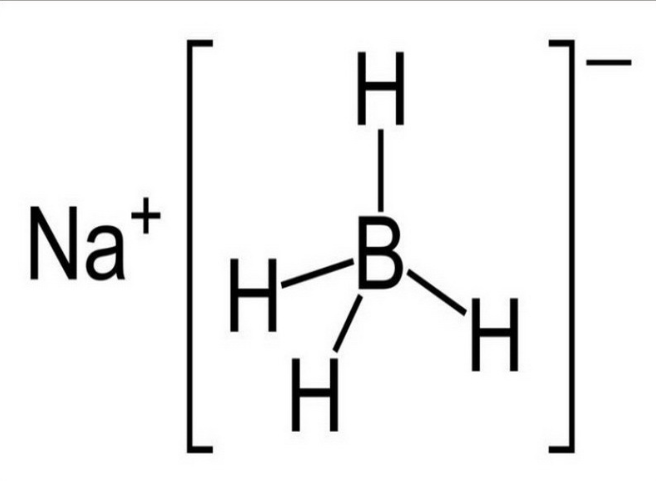

| Product Name: | Sodium borohydride |

| Synonyms: |

SBH

1H-borole

VenPure? SF

Sodium borohydride

sodium boron(-1) anion

Sodiumborohydridepowder

Sodium tetrahydroborate

Sodiumborohydridepellets

Sodiumborohydridetablets

Sodium tetrahydridoborate

Sodiumborohydridewhitepowder

Sodiumborohydrideonneutralalumina

SodiuM borohydride solution 2.0 M in triethylene glycol diMethyl ether

|

| CAS: | 16940-66-2 |

| MF: | BH4Na |

| MW: | 37.83 |

| Appearance: | white crystalline powder |

| Boiling point | 500°C |

| density | 1.035g/mLat 25°C |

| melting point | >300 °C (dec.) (lit.) |

| boiling poin | 500°C |

| Solubility | 550 g/L (25 ºC) |

| sensibility | Hygroscopic |

| Physico-chemical property | White crystalline powder. The relative density is 1.074. Decomposes at a vacuum of 400 ° C. It is hygroscopic, stable in dry air and decomposes in wet air. Soluble in water, liquid ammonia, amines, slightly soluble in tetrahydrofuran, insoluble in ether, benzene, hydrocarbons. It reacts with water to produce hydrogen. Sodium borohydride alkaline solution is brownish yellow. |

| Physical properties | Diethyl(phenylacetyl)malonate has a boiling point of 500°C(Predicted). Its density is predicted to be 1.035g/mLat 25°C |

| Uses | It is a good reducing agent, which is characterized by stable performance and selectivity in reduction. It can be used as a reducing agent for aldehydes, ketones and acyl chloride, a blowing agent for plastics, a hydrogenating agent for the manufacture of dihydrostreptomycin, an intermediate for the manufacture of potassium borohydride, a raw material for the synthesis of borane, and a treatment agent for the paper industry and mercury-containing sewage. Or fuel cell hydrogen source carrier. |

| Preparation | Sodium borate methyl ester process; Boric acid and an appropriate amount of methanol were added to the distillation kettle, heated slowly, and fully reflow for 2h at 54℃. Then methyl borate and methanol azeotrope were collected. The azeotrope was treated with sulfuric acid and purified after distillation. The sodium hydride obtained by the action of hydrogen and sodium is sent into the condensation reaction tank, heated to about 220 ° C under stirring, methyl borate is added, and the heating is stopped at 260 ° C. I The feeding temperature is controlled below 280 ° C, and continue to stir after feeding to make it fully react. After formation, the product was cooled to below 100℃ and centrifuged to obtain the condensed product filter cake. Add appropriate amount of water to the hydrolyser, slowly add the filter cake to the hydrolyser, control the temperature below 50℃, after the feeding is completed, the temperature rises to 80℃, centrifuge separation, the hydrolysate is sent to the stratifier, static for 1h after automatic stratification, the lower hydrolysate is sodium borohydride solution. |

Q1,What's your MOQ ?

Usually our minimum order quantity is 1kg.

Q2,How do you assure your quality?

All of our products are strictly tested by our QC before we package them so there's no need to worry about it.

Q3,How long does it to deliver?

It depends on your destination,generally 5-15 days by air and 20-35 days by sea.

Q4,May I get a sample?

Definitely yes. For most products we can provide you a free sample and you just need to pay for the shipping

fee or send us your agent to take the goods for you.

Q5,May I get any discount?

Of course.For different quantities we offer different discounts.

Q6, How’s your after-sales service?

Never worry about it,any problems please just feel free to contact our sales staffs and you will get a response ASAP.

Q7,Is there any present for your customers who do business with you for a long time?

Sure.We do prepare presents for our customers on their holidays.

Q8,How about the quality of the company's products?

Please rest assured that our products are of the highest quality.

Q9,How about the quality of the company's products?

Please rest assured that our products are of the highest quality.